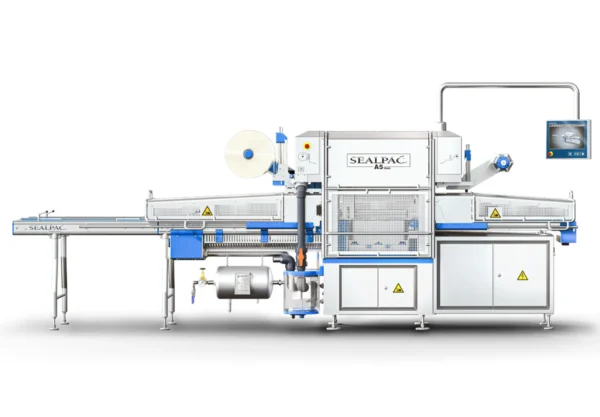

SEALPAC A5max Traysealer

Up To 70 Packs Per Minute

For complete packaging line integration, contact us to explore denesting options

Product Highlights

- Servo controlled film transport

- Numerous in-feed systems for all types of trays

- Pneumatic tooling quick exchange system; no hand tools necessary

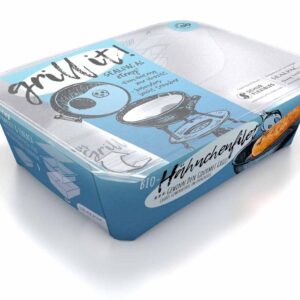

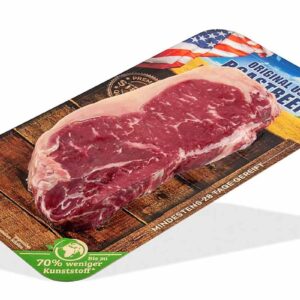

Applications

Bacon / Bakery / Beef / Cheese / Confectionery & Nuts / Convenience Foods / Cooked and Smoked / Deli Meat / Dry and Semi Dry / Fruits & Vegetables / Lamb / Pet Food / Pork / Poultry / Processed Meats / Seafood / Vegetarian/VeganAsk an Expert

Request Callback | Email

Product Overview

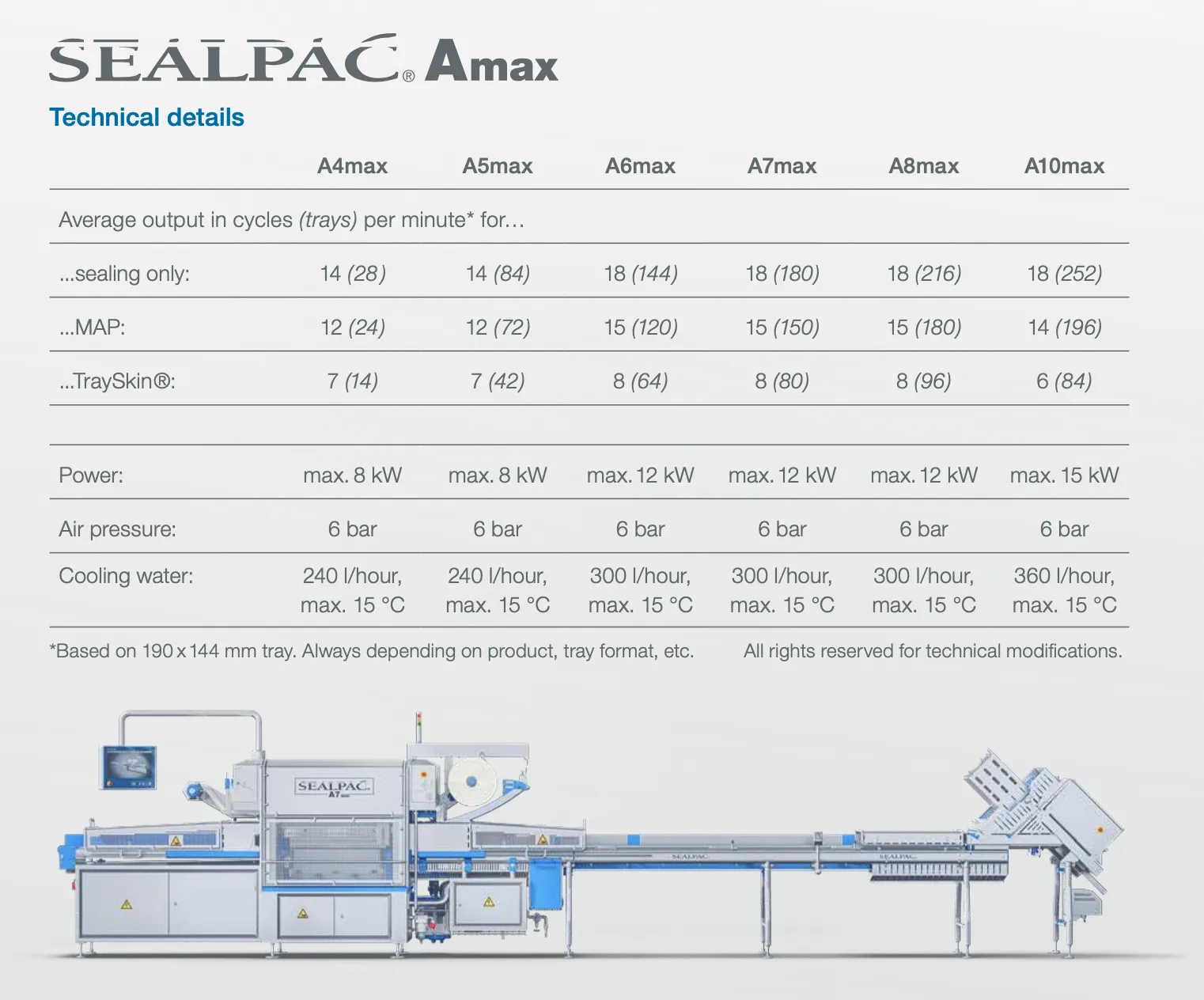

SEALPAC A5max Traysealer brings a professional approach through its compact design and complete performance that can be crucial in industrial processing even at entry-level. This fully automated unit combines all the benefits of larger models in a space-saving format.

This machine allows for both left and right hand operation with the tooling exchange system from both sides. The flexible tray heights, in-house manufactured low-maintenance gas valve, servo controlled and tailor-made tray transportation systems of the SEALPAC A5max Traysealer make it a flexible solution for cold or hot fill individual applications, MAP (Modified Atmosphere Packaging) or TraySkin® packaging.

Downloads

Features

- RFID system recognizing tools and grippers

- Futureproof design for growth, integration, and future packaging changes

- User Friendly interface with various security levels to maximize throughput & uptime

- Machine can be operated on either side

- Integrated channels and connections of the tooling

- Intuitive operator touch screen panel up to 100 programs

- Servo controlled film transport

- Seamless integration into current product lines

- Individual sealing packages for highest sealing integrity

- Secure tray guidance in all sequential stages

- External communication interface

- Wash-down stainless steel frames

- Self-draining hygienic construction