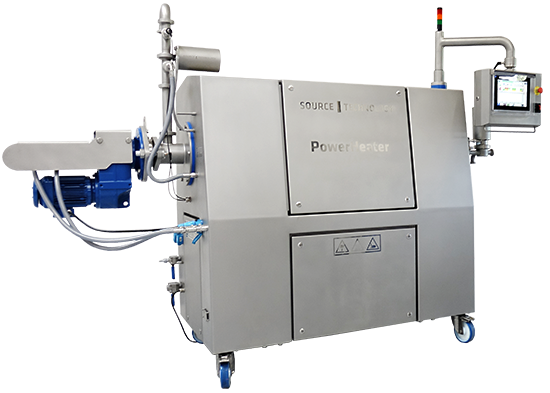

PowerHeater™

100, 100-3, 100-5

Brand

Source Technology

Product Highlights

- 100-1500 kg/hour (200 – 3000 pounds/hour)capacity

- Low steam with low pressure creates high quality textured products

- Transform low cost simple formulas into high quality value added product lines

- Great fit for both the plant based and meat industries

Ask an Expert

Request Callback | Email

Compatible Innovative Products

Product Overview

The PowerHeater technology is based on the principles of extrusion technology. The PowerHeater process is based on transferring mechanical and thermal energy into a meat emulsion in order to coagulate the protein and any potential sources of carbohydrate. This technology transforms simple formulations into a highly textured meat like product.

Features

- Product Temperature: Inline temperature monitoring for consistent product and documentation for food safety programs

- Product Bypass: Automatic bypass valve that opens when product doesn’t meet minimum temperature requirements

- Pressure Control: Automatic pressure control system regulates product pressure and temperature along with pump pressure to ensure optimal process stability

- Flush System: The PowerHeater is automatically flushed with water. Valves will automatically adjust to generate a high-pressure water flow in order to flush the machine as part of its general cleaning and sanitation.

- Fully Automated Process Control: All parameters are governed by the HMI. An automatic start-up and shut-down sequence allow for minimum of operator interference.

- Heating: The PowerHeater is heated using indirect steam and is controlled through an automated process.

Specifications

Coming Soon.