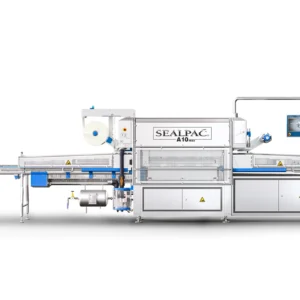

SEALPAC A10max Traysealer

For complete packaging line integration, contact us to explore denesting options

Product Highlights

- Servo controlled film transport

- Numerous in-feed systems for all types of trays

- Pneumatic tooling quick exchange system; no hand tools necessary

Applications

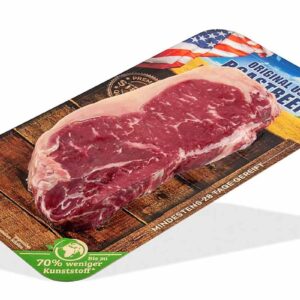

Bakery / Confectionery & Nuts / Convenience Foods / Fruits & Vegetables / Seafood / Vegetarian/Vegan / Beef / Cheese / Lamb / Pet Food / Pork / Poultry / Processed Meats / Bacon / Cooked and Smoked / Deli Meat / Dry and Semi DryAsk an Expert

Request Callback | Email

Product Overview

The SEALPAC A10max Traysealer provides top performance with its servo technology, and is available in single and double lane construction. This easy to operate elite class machine offers a trouble free fully automated process in high capacity production runs.

The unique and quick retooling exchange system with left and right hand operating access, simple format alternation, and hygienic design result in a low down time solution. Wear-resistant gas and vacuum valves, flexible tray heights, and solid stainless steel construction are other special features of our elite class. The SEALPAC A10max Traysealer is extremely suitable for producers of fresh meat, fresh poultry, deep-frozen, and convenience foods in high volumes.

Downloads

Features

- RFID system recognizing tools and grippers

- Futureproof design for growth, integration, and future packaging changes

- User Friendly interface with various security levels to maximize throughput & uptime

- Machine can be operated on either side

- Integrated channels and connections of the tooling

- Intuitive operator touch screen panel up to 100 programs

- Servo controlled film transport

- Seamless integration into current product lines

- Individual sealing packages for highest sealing integrity

- Secure tray guidance in all sequential stages

- External communication interface

- Wash-down stainless steel frames

- Self-draining hygienic construction