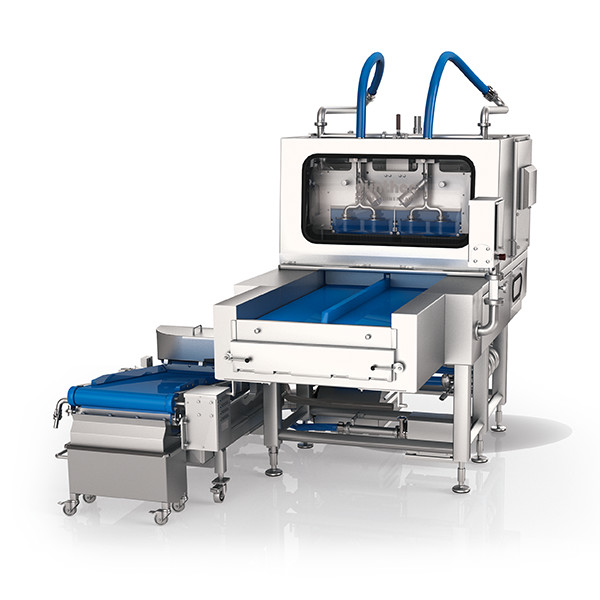

Gunther Injectors for Poultry Processing

Brand

Günther

Product Highlights

- Injection pattern with a high needle density for the best possible brine distribution in the product

- Product-specific needle selection to reduce visible punctures

- Product-specific filter selection (belt filter, double pre filter, self-cleaning filter)

- Higher output through product-specific clearance height adjustment

- Injection quantities from 5% – max (product-dependent)

Ask an Expert

Request Callback | Email

Product Overview

The Günther injectors for poultry processing are uniquely engineered with the fully automatic reversible servo injector. This offers a higher degree of precision and more consistent control for greater product uniformity.

PIH series injectors were developed specifically to handle injections required by various types of poultry products. Different size machines within the series cover all production capacities from small operations to larger, industrial facilities. The injection patterns utilizes a high needle density for the best possible brine distribution in the product. The series offers product-specific needle selection to help reduce visible punctures on the product. A product specific clearance height adjustment supplies the operator with higher output. Greater precision, consistent control and product specific injection make this line the premier choice for poultry processing operations of any size.

Downloads

Features

The machine can process poultry legs, wings or breasts in separate lines with the same or with different injection quantities.Needle cassettes with product-specific needles can be replaced within a few seconds. Each line works independent from the other and offers specific, product-related advantages.

New

- New drive concept Günther Reverse II

- Optional patented individual needle detection system and flow monitoring and detection of individual damaged needles

- Optional dynamic stroke mode

- Easy operation and ergonomic industrial design

- Direct drive via servo technology

- Precision needle heads with quick change (release) needle-bridge-system

- Complete separation of pump cycle from all electromechanic components

- Product related pump selection

- Pre-filter system electronically supervised

- Automatic rotary filter units

- Process parameters infinitely variable

- Special conveyor from polyethylene, easy to remove for sanitation

- MC2R-control with touch-screen

- 100 memory spaces for recipe storage

- Infinitely variable stroke height selection

- Number of strokes up to 50 st/min

- Automatic stand-by mode for needle head and brine circulation

- Highest injection precision supported by position controlled brine valve

- Automatic sanitation program

- USB/Ethernet and CAN-Bus standard

- Individual tension control