Günther Industrial Heating/Cooling Tiltable Vacuum Tumbler/Massager

Product Highlights

- Maximizes drum volume utilization

- Handles larger load capacities

- Easy to empty

- Easy to clean

Applications

Bacon / Beef / Cheese / Cooked and Smoked / Deli Meat / Lamb / Pet Food / Pork / Poultry / Processed MeatsAsk an Expert

Request Callback | Email

Product Overview

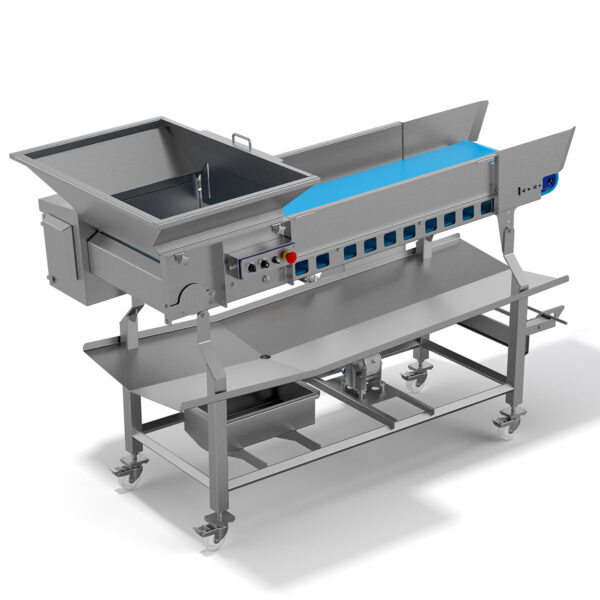

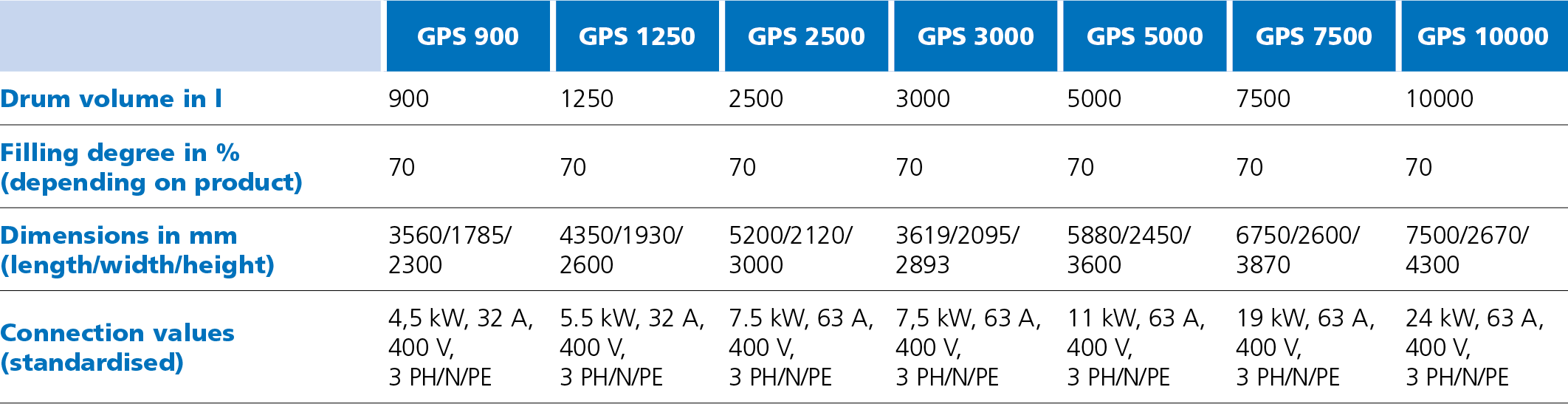

The GPS series of industrial tumblers from Günther offer operators a high utilization factor of up to 60% of the drum volume, for optimal quality processing of small fills to larger load capacities. In addition to volume, an essential feature is the swiveling drum with a large, automatically operated door, making the drum easy to empty and gentle on drum contents. The design also makes it easy to clean. Simple menu navigation with touch screen controls enable automatic set-up and consistent processing control from batch-to-batch, including and up to angle of inclination and the selected direction for rotation.

Downloads

Features

- Drum geometry with large circumference

- Asymmetric baffles with interaction

- Modern touch-screen control with graphically guided operation and programming

- 100 programs, each with up to 10 steps

- All process parameters can be freely controlled and programmed, such as lead time, processing time, pause time, vacuum, temperature, angle of inclination, speed, selectable direction of rotation

- Simple menu navigation, convenient recipe management, administration and documentation of workflows, extensive diagnostic tools, remote maintenance, highly accurate temperature control based on brine cooling

- The desired production end time is freely selectable and can be preset, i.e. no need for any preliminary calculation regarding start of production, idle time, etc.

- Load cells

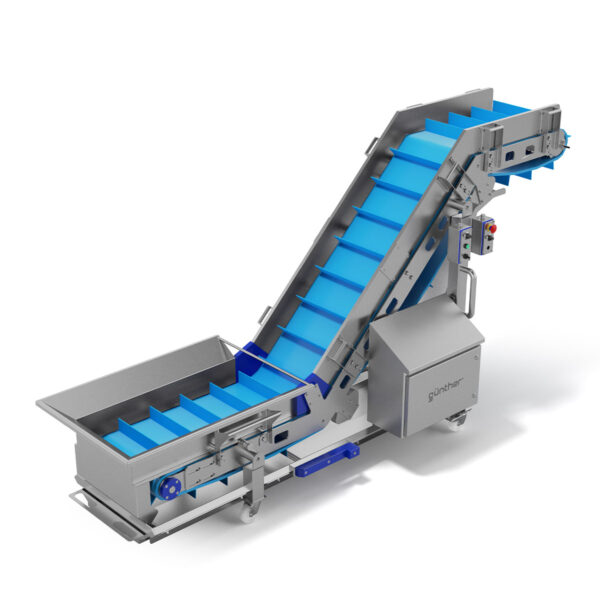

- Feed system

- Wireless temperature monitoring of products

- Cooling and/or heating machines

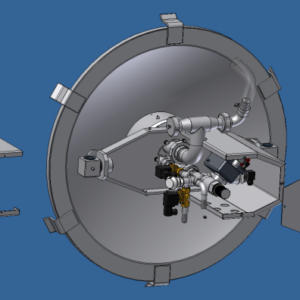

Add on to all Günther defrosting Tumblers GPS: GTT – Günther Thawing-Technology is a unique process combination of direct and indirect heat transmission. In addition to the standard defrosting application with indirect glycol heat transmission through double jacket and baffles, the system generates a hot vapor phase injected into the drum and surrounding the meat blocks. This results in faster defrosting with minimal product denaturation.

The system contains the following components:

- Special drum cover including centric connection for vacuum, temperature sensor, water supply, as well as all necessary valves, cable and hose connection

- Stand-alone flow heater for temperatures up to 80°C

- Supply pump for water

- Electronic temperature and flow control

New

- Pilot Pro Data Collection