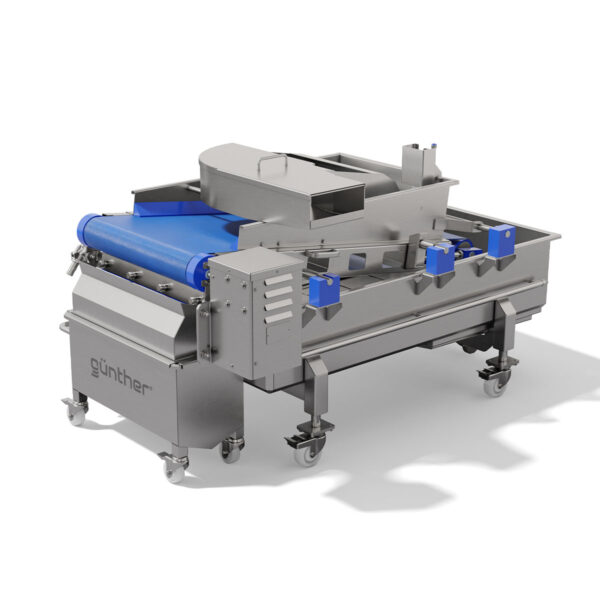

Günther Craft Injectors

PI 265-17, PI 280-21M, PI 345-26M, PI 345-52M

Product Highlights

- Rugged construction

- Compact design

- High injection accuracy

- Simple operation

- Low maintenance

- High flexibility

- Easy to clean

Applications

Bacon / Beef / Cooked and Smoked / Deli Meat / Lamb / Pet Food / Pork / Poultry / Processed Meats / SeafoodAsk an Expert

Request Callback | Email

Product Overview

The automatic pickle injectors from Günther offer processors a machine with rugged construction for long-lasting operation and service. The compact design occupies a small footprint within the plant, yet offers flexibility within the series to process a wide variety of applications, depending on processing requirements. Individual machine specifications offer additional information on the application potential. Overall, the Günther pickle injectors are easy to operate, clean and maintain. Precision injection accuracy streamlines production and increases output for an excellent return on investment.

Downloads

Features

PI 21M, PI 26M, PI 52M

- Direct mechanical drive for needle head and belt above the pickling compartment

- Precision needle heads with quick-change needle bridge system

- Mechanical suspension of each needle for products with bones

- Complete separation of the entire pumping cycle from all electromechanical components

- Standard stainless steel centrifugal pump

- Product-related pump selection

- Pre-filter system

- Special conveyor belt made of polyethylene, easy to remove

- Injection pattern can be varied by mechanically changing the conveyor belt feed settings

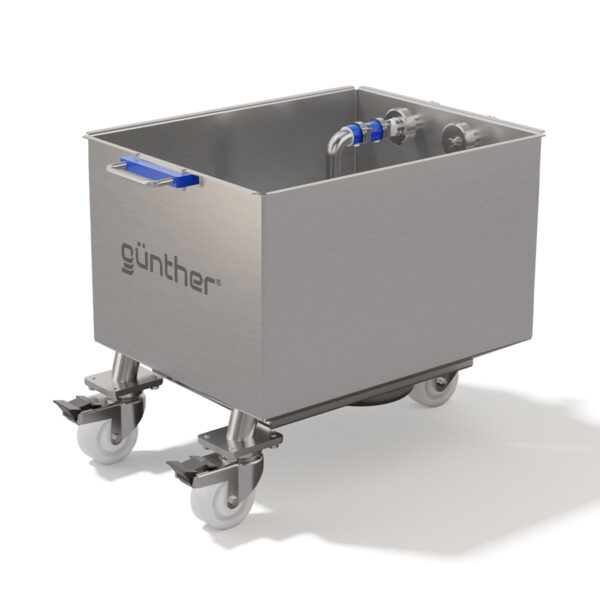

- Optional semi-automatic filter system GHF

- Optional H version for fish and poultry

PI 21M

- Additional M-controller for infinitely variable control of process parameters and 20 program locations for recipe management

PI 17 available upon request