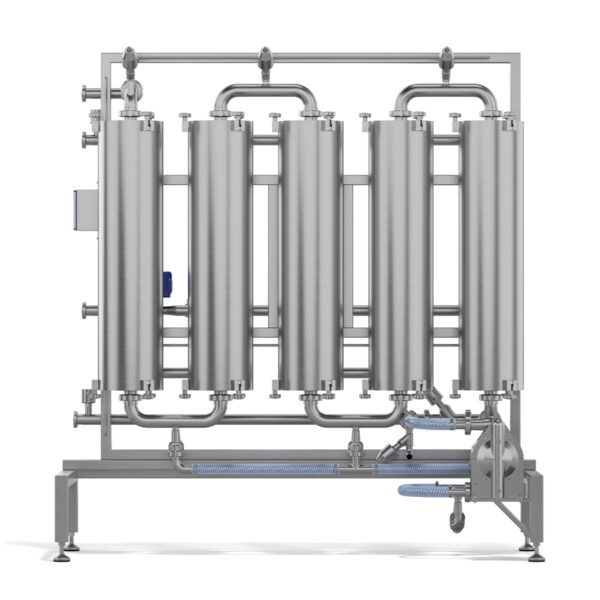

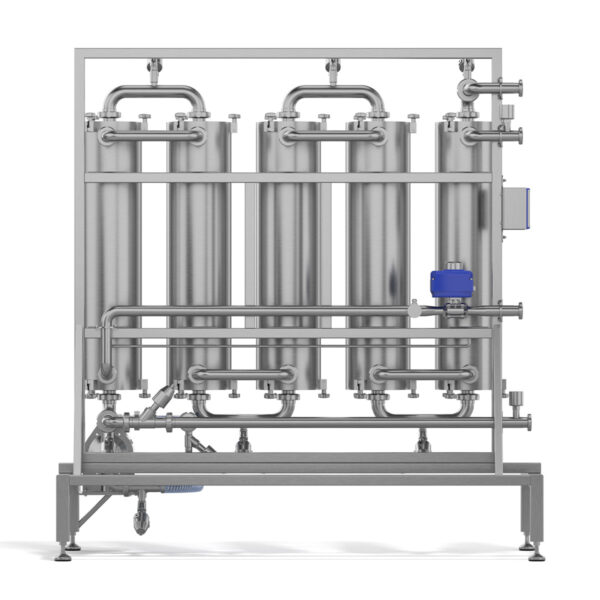

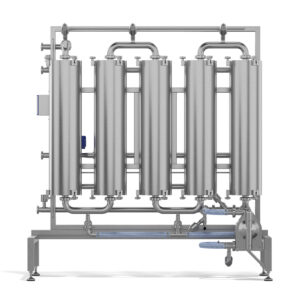

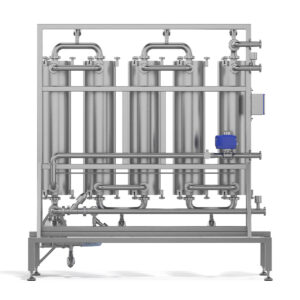

GRK Tube Coolers & GSK Cooling/Heating Machine

GRK, GSK

Product Highlights

- Fast and efficient cooling of already mixed brine in a continuous process

- Reducing the temperature input into the product

- Hybrid operation as cooling/heating combination possible

- Easy to clean thanks to the stainless steel construction

- Stand-alone-operation through integrated control unit

- Counterflow-based shell and tube heat exchangers

- Monitoring and traceability because of the temperature regulator with temperature sensors

Ask an Expert

Request Callback | Email

Product Overview

Pipe cooler for cooling brine and sauces in a continuous process. Unplanned downtime due to heated brine is a thing of the past with the Günther pipe cooler system. In the integrated system and in-line process, Günther pipe coolers ensure consistent cooling of brines and sauces, even with large production volumes.

Perfect combination of tube coolers and cooling unit, optimized energy-efficient coordination.

Injection: Better control of the brine temperature over long process times.

Brine preparation and preservation: optimum adjustment of the brine temperature during preparation, cooling of the double jackets GMA / GLT

Tumbler: In combination for use as GTT thawing technology, as GSK is for efficient, coordinated cooling of the tumbler containers.

Downloads

Features

- The heat exchanger is designed for connection to an existing on-site cooling system as well as to a Günther cooling unit

- Control package for stand-alone operation

- Stainless steel control cabinet

- Speed-controlled 2,2 kW centrifugal pump

- Temperature controller with temperature sensors

- Electric ball valve for brine circuit

- Control package for line operation

- Speed control for pump station

- Temperature control with temperature sensors

- Electric ball valve for brine circuit

- Pumping station for line application between filter and GRK