Günther Tumblers/Massagers

Günther Tumblers/Massagers

The reason, principle, or process of tumbling and/or massaging meat products in the further processing industry is to physically work the individual muscles in an enclosed vessel under vacuum. This mechanical action to work, limber, and even tenderize the muscles is to allow the injected or free brine marination (ingredients) to do their job. Their job consists of breaking down or opening the muscle fibers to extract protein. Protein in the meat/muscles serve as the glue to literally put meat blocks back together while aiding in the cure color of meat during the heating or cooking process. Manipulating this process under vacuum is a key to speeding the process up and creating consistency in a shorter period for the meat processor. Controlling and monitoring this process improves consistency in the quality of products while maximizing yields.

Versatility

The Günther tumbler/massager is an excellent tool of the trade by offering simple small pieces of equipment for the small or mid-tier customers all the way up to the large industrial recipe driven machine units for the large processors. These tumblers/massagers also have the features of jacketing the vessels to both cool/chill or heat/raise the temperature of the meat block during the tumbling/massaging process. People can refer to this also as a double wall unit. The heating function can also be used to thaw or defrost products. There are also units that range from a standard horizontal vessel to vessels that include tilting to achieve different angles of the vacuum vessel itself. All of these allow for less or more action to the meat/muscles creating the customer’s desired product.

Variations

The Günther tumbler/massager line ranges from the simple on/off units to ones with PLC driven units that allow the input of individual recipes. Horizontal and tilting units have the options to add load cells or weigh cells. Another option or accessory available by Günther is the addition of vacuum loading hoppers for the ease of loading batches of products quickly, clean, and easy.

Cleaning and Maintenance

Sanitation features lead the industry with highly polished and mirror finished stainless steel surfaces which aid in cleaning and sanitation of the units. Shortening the cleaning and sanitation process allow each producer to maximize their up time or hours to produce.

Find The Right Günther Tumbler/Massager for Your Application

-

GHK Loaders

-

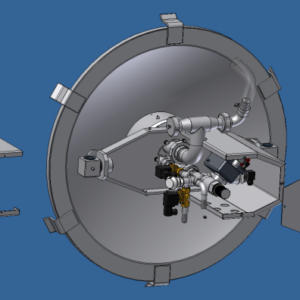

Günther Industrial Heating/Cooling Tiltable Vacuum Tumbler/Massager

-

Günther Flexible Tilting Vacuum Tumblers/Massagers

-

Günther Freeze & Coating Tumblers

-

Günther Horizontal Industrial Tumblers/Massagers

-

Günther Small/Mid-size Tiltable Vacuum Massaging Tumblers

-

Günther Drainage Tumblers

-

Günther Defrosting/Thawing Tumbler Drum Lid

-

Günther Intelligent Brine Chilling & Heating Unit