Günther Freeze & Coating Tumblers

Product Overview

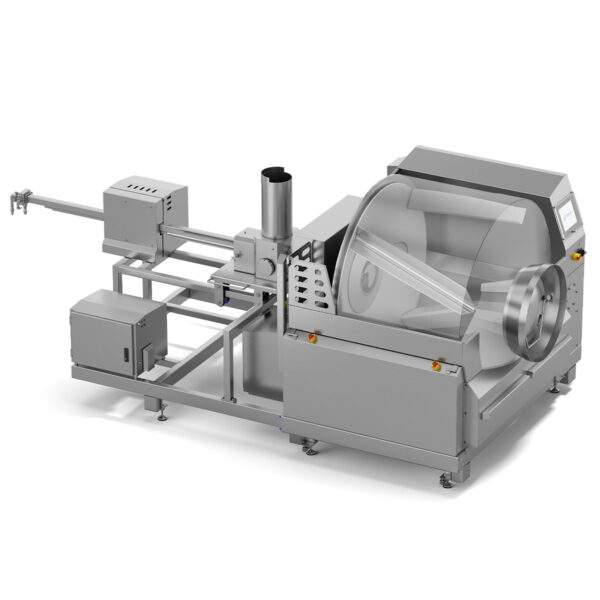

Tumbler coating with liquid nitrogen

High quality prepared meals, especially ready-to-serve, are in high demand. The “Günther tumbler” enables processors to meet this demand by coating frozen foods with a light, even coating of seasonings or sauces for a finished product that delivers savory flavor without lumps, clumps or breaks.

Functional principle

The deep-frozen, loosely rolling base material (meat, vegetables, rice, pasta etc.) is fed into the tumbler drum by conveyors and/or lift loaders. (In the case of lift loaders proper temperature needs to be maintained, between -18°C to -20°C).

The material is mixed and sprayed with liquid nitrogen in the tumbler. The liquid nitrogen then passes into the gas phase and subcools the base material to e.g. – 50°C. The subcooled material is sprayed with sauce as it tumbles in the drum. The large temperature difference immediately solidifies the sauce solidifies to form a uniform coating.

Drum speed influences the mixing quality, the surface to be sprayed and the duration of the process. Throughput of liquid nitrogen or sauce to control the spraying effect and the required time, depending on the pressure, number and shape of the nozzles, and the viscosity/ temperature of the sauce.

Liquid nitrogen as an ideal refrigerating agent

Liquid nitrogen allows for faster freezing, forming smaller ice crystals to help retain and preserve product moisture and quality. It acts as the ideal agent for coating processes, locking in product moisture yet not injecting moisture into the coating itself, allowing for greater adherence of the seasoning, coating or sauce. In addition, liquid nitrogen processes help prevent microbial growth, speed production by reducing cycle times to increase product throughput. The refrigerating agent nitrogen is easy to apply and environmentally-friendly. In summary, the “Günther tumbler technology” in conjunction with liquid nitrogen gases offers processors the smart solution for coating and freezing prepared meals, snacks, appetizers and meal components in an efficient manner.

Downloads

Features

- PERFECT CLEANING Flow-jet nozzles and optimally movable lances for perfect cleaning of stainless steel surfaces

- TRIED AND TESTED COATING LANCE TECHNOLOGY Various thermal lances wit quick-change nozzle system

- CONTROLLABLE SPRAY PATTERN Precise adjustment of the nitrogen and sauce flow rate

- INDIVIDUAL CHARGING VERSIONS Belts, screw conveyors, funnels to suit your application

- PLANT TECHNOLOGY FROM ONE SOURCE Günther Product Line Solutions